Innovative technology

Energy from Waste

We use a specific treatment technology to process and recycle mixed wastes unsuitable for material recovery, meeting sustainability objectives by generating electricity and heat. By producing syngas, the technology also facilitates chemical recovery.

For successful application of the technology, material streams need to be pretreated i.e. shredded and homogenized, with the proportion of inorganic substances reduced. Pretreatment requires various processes, depending on the stream. Syngas purification should also match the characteristics of material streams at each site.

Process steps

- Heating up the treatment reactor

- Continuous feeding of pretreated raw material of appropriate shred size into the process

- Materials fed into the reactor decompose gradually in low-oxygen conditions, generating syngas

- Removal of syngas from the reactor

- Purification of syngas

- Purification of syngas

- Temporary storage of syngas as required (buffer tank)

- Using syngas to fuel a gas engine, optional heat recovery (mantle heat, emission heat)

- Feeding the generated power into the grid, sale of electricity

- Removal of residual solids from the reactor, as necessitated by the quality of the material stream

- recovery (e.g. residual soot from rubber processing)

- disposal in landfill

The technology is suitable for processing organic materials and organic waste.

Main material streams to be treated:

- Pretreated municipal waste (RDF / SRF)

- Tires

- Mixed packaging waste unsuitable for material recovery

- Hazardous waste e.g. contaminated paper and plastic packaging after shredding

Molecular thermolysis and energy recovery plant

By means of molecular thermolysis, organic waste is turned into syngas.

The difference between molecular thermolysis and waste incineration is that the former produces syngas. In molecular thermolysis, waste is not used as fuel, but as feedstock for a high-temperature thermolytic process.

Instead of just generating heat and electricity, as waste incineration plants do, a molecular thermolysis plant will also produce syngas which in turn can be used to produce valuable commercial products such as fuels, chemicals, fertilizers or even as substitute natural gas.

While molecular thermolysis and incineration are both thermal processes, it is important to highlight the advantages of the former over the latter.

Incineration is simply a mass combustion technology with heat recovery that produces steam and/or electricity. It is rejected by the public because of the emission of dangerous carcinogenic compounds (such as dioxins and furans) produced by the direct incineration of waste.

Advantages of molecular thermolysis over waste incineration

During molecular thermolysis, waste is transformed into syngas which in turn may be used to produce:

- steam and/or electricity

- valuable products

- chemicals

- liquid fuels

An important benefit of molecular thermolysis is that the syngas produced can be cleaned of contaminations before use, thus eliminating various emissions that are associated with the use of post-combustion emission control systems in incinerators.

Clean syngas can be used in reciprocating engines or turbines to generate electricity, or may be further processed to produce hydrogen, substitute natural gas, chemicals, fertilizers or fuels for transport.

Process capacity data

Waste processing capacity

• Processing capacity of pretreated waste: approx. 1 ton/h; annual processing capacity: approx. 7500 tons/year

• Raw waste processing capacity approx. 15,000 – 20,000 tons/year

Residual waste

Depending on the composition of waste, between 15% and 30% of residual waste is generated. It is disposed of by landfilling.

Operation

320 operating days per year; 3 shifts - 7680 hours/year – approx. 87.6% availability

Maintenance

45 days of maintenance per year - 1080 hours

Performance

1 MWh syngas output

Gas engine

1 MW rated power, designed to be fueled by syngas

Electricity

Syngas production followed by controlled electricity production from buffer tank

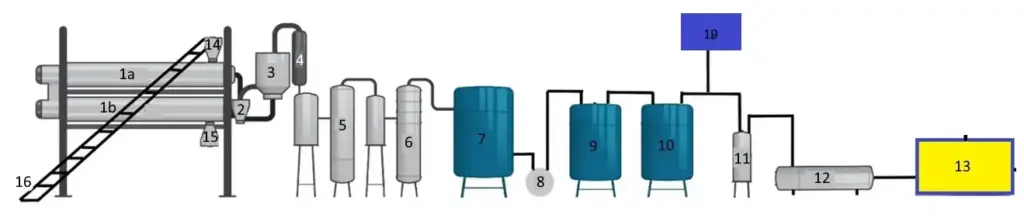

Description of the thermolytic system

The conveyor belt (16) transports the waste to the molecular thermolysis reactor (1). The reactor has the following components:

– a primary reactor (1a) at the top and

– the secondary reactor (1b).

The operating temperature of the primary reactor (1a) is between 680 and 1050 °C. This temperature is maintained by electric heating. The raw material stays in the primary reactor for 5-12 minutes. In the primary reactor, the raw material is partly decomposed i.e. volatile products are removed, its moisture content is partly decomposed and free carbon is partially activated.

From the primary reactor (1a), the raw material is transferred to the secondary reactor (1b) located below the primary reactor. The operating temperature of the secondary reactor is between 400 and 800 °C.

The thermolytic reactions in the reactor result in the production of:

– ash and

– gases.

Legend

- Thermolytic reactor

- Cyclone separator

- Tar filter

- Heat exchanger

- Desulfurizer

- Heavy metal filter

- Heat exchanger

- Vacuum pump

- Gas filter

- Gas filter

- Compressor

- Finished product tank

- Generator

- Dosing tank for raw materials

- Ash collection tank

- Conveyor belt

- Gas burner (emergency)

The ash is removed from the reactor (1) through a special exhaust tank (15), with all the connections properly sealed. This tank has a capacity of about 1 m3. It is emptied into containers as required by the production volume. The collected ash can be used in the production of construction materials, cement or asphalt.

The gases from molecular thermolysis are extracted continuously by a vacuum pump (8) and transported to the cyclone separator (2), where the fine ash particles carried by the gases are separated.

From the cyclone (2) the gases pass to the tar filter (3), which is filled with a mixture of zeolites, dolomite and coal. This filter operates at temperatures between 900 and 1100 °C. From the tar filter (3) the gases pass to the heat exchanger (4) where they cool down.

From the heat exchanger (4), the gases pass to the desulfurizer (5) and the heavy metal filter (6). These filters consist of several layers of molecular sieves (zeolites) of various particle sizes.

From filters (5) and (6) the gases pass to the heat exchanger (7) where they are cooled to 40 °C.

From the heat exchanger (7), the gases pass through the additional filter system (9) and (10) to get a fully neutral pH and are then compressed in the storage tank (12) by the compressor (11).

The gas burner (17) starts only in emergency situations, when surplus gases that cannot be stored or when the CHP system is not operating.

The resulting gas (syngas) contains carbon monoxide, hydrogen, methane, carbon dioxide and nitrogen. The estimated composition of the syngas obtained from the process varies, depending on the composition of the feedstock. When municipal waste is fed into the process, the typical composition of the syngas is:

– methane 40.4 mol%

– carbon dioxide 7.4 mol%

– carbon monoxide 18.8 mol%

– hydrogen 18.6 mol%

– ethane 3.1 mol%

– nitrogen 6.8 mol%

– other gases 4.9 mol%

CHP phase

From the finished product tank (12), the gases are fed into the gas engine of the generator (13) and electricity is produced which in turn can be fed into the grid. Cogeneration also generates heat which can be utilized in various ways.

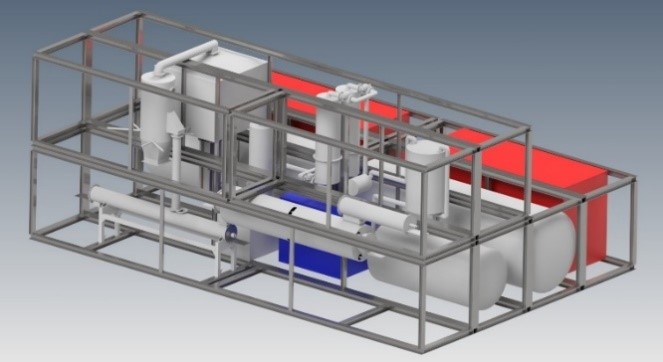

Net land requirements of the technology

The treatment plant has a modular design with a container-based structure. It has the following dimensions: (H) 12 m x (W) 4 m x (H) 5 m.

Installation is automated with local PLCs communicating continuously with the SCADA system. This design provides for the monitoring and control of the processes.

Operation requires 1 front loader and multilift containers of 24/30 m3.

Contact

Please contact us at one of the options below or use our online Contact Form.